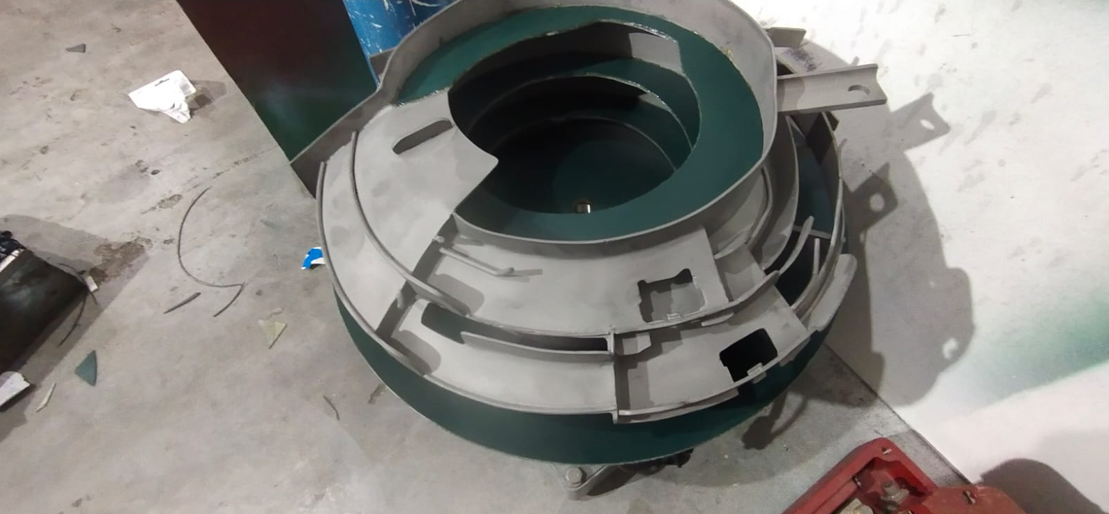

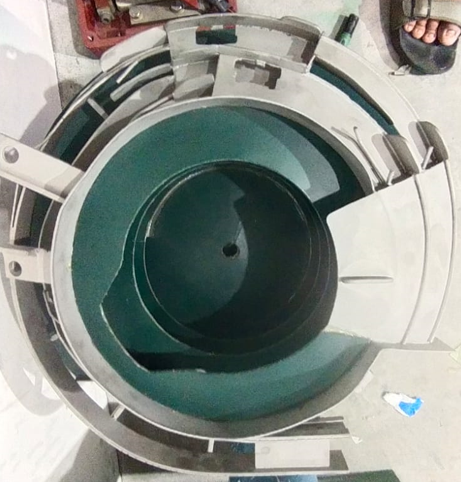

SANDBLASTING

Sandblasting, also known as abrasive blasting, is a process used to clean, roughen, or shape a surface by propelling abrasive material at high velocity. Here’s a detailed look at how it works and its applications:

How Sandblasting Works:

Abrasive Material: The process involves using an abrasive medium, such as sand, glass beads, or metal grit. Despite the name, modern sandblasting often uses materials other than sand, like aluminum oxide or silicon carbide, which are more effective and safer.

Blast Equipment: The abrasive material is propelled by a stream of compressed air or another type of pressurized gas through a nozzle. The equipment typically includes:

- Blast Pot: Holds the abrasive material and supplies it to the blast nozzle.

- Compressor: Provides the compressed air needed to propel the abrasive material.

- Blast Nozzle: Directs the flow of abrasive material onto the surface.

- Protective Gear: Operators wear protective clothing, including goggles, gloves, and sometimes helmets or suits, to guard against the abrasive particles and dust.

Surface Treatment: The abrasive particles strike the surface at high speed, removing contaminants, old coatings, or rust. The force and impact can also etch or roughen the surface, which can be important for improving adhesion for subsequent coatings or finishes.

Collection and Recycling: In many sandblasting setups, used abrasive material is collected, cleaned, and recycled for repeated use, which makes the process more cost-effective and environmentally friendly.

Applications of Sandblasting:

Surface Preparation:

- Cleaning: Removes rust, old paint, grease, and other contaminants from metal, concrete, and stone surfaces.

- Etching: Creates patterns or textures on glass, stone, or other materials for decorative purposes.

Surface Profiling:

- Roughening: Prepares surfaces for better adhesion of paints, coatings, or adhesives.

Repair and Restoration:

- Restoration: Used to clean and restore historical buildings, monuments, and antique items without causing damage.

Manufacturing:

- Deburring: Removes sharp edges and imperfections from metal parts in manufacturing.

Advantages:

Efficiency: Sandblasting is a fast and efficient method for cleaning and preparing surfaces.

Versatility: It can be used on a wide variety of materials, including metal, glass, wood, and concrete.

Customization: Different abrasives and nozzle sizes can be used to achieve specific finishes or levels of cleanliness.